How to Secure Injection Molding Services with Chinese Suppliers

The important meeting has recently finished, your new project has the green light, time is pressing, and the budget is… well, let’s just say it’s tight.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. The cost savings can be huge. Yet your thoughts are already spinning. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Sourcing plastic mold company can be a calculated project. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Here’s a practical playbook to nail it.

First Things First: Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You cannot expect overseas partners to interpret your unspoken requirements. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

What should you include?

Begin with 3D CAD models. They cannot be skipped. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

But 3D isn’t enough. You also need detailed 2D drawings. Here you specify what 3D can’t show. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Get precise. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why so detailed? Because there are thousands of plastic variations. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Lastly, add your business data. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

With your RFQ perfected, who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Finding suppliers is simple; finding quality ones is tough.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. Aim for a preliminary list of 10–15 potential partners.

Still, you must dig deeper. Think about engaging a sourcing agent. True, they charge a fee. But a good one has a vetted network of factories they trust. They handle local liaison and oversight. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Tap your professional contacts. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

With your RFQ dispatched to dozens of firms, estimates roll in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It blends technical checks with intuition.

Begin with responsiveness. Are their replies prompt and clear? Do they communicate effectively in English? The true litmus: are they raising smart queries? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” Consider that a big green light. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Request their machine list. Seek samples or case studies of comparable projects. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Finally, inspect the factory. This is not optional. Just as you interview hires, audit suppliers. You can travel or outsource a local inspector. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s a tiny cost for huge peace of mind.

From Digital File to Physical Part

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Then comes the real action.

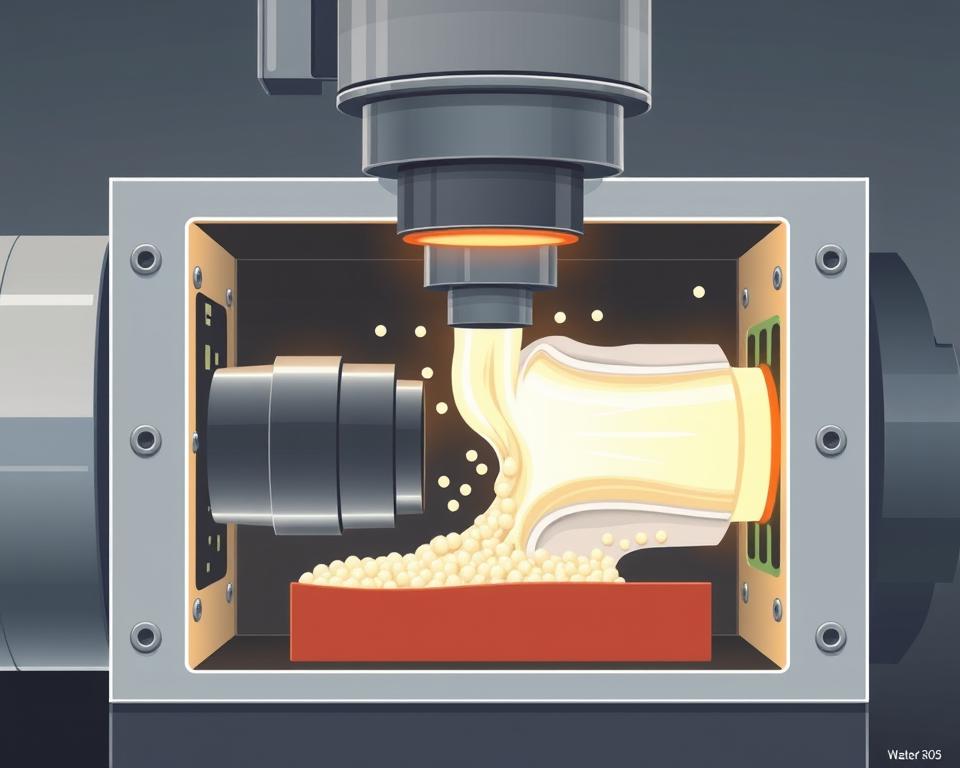

Initially, expect a DFM report. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A thorough DFM is a sign of a professional operation. It’s a collaboration. Together, you tweak the design for best manufacturability.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. It’s your test of success.

Be prepared: T1 samples are almost never perfect. It’s par for the course. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold in China samples follow. You may repeat this cycle a few times. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Eventually, you will receive a part that is perfect. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Often, you hire a pre-shipment inspection service. Bring in an external QC firm. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This step saves you from a container of rejects.

Don’t forget shipping details. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.